A Csaba Metál Zrt., one of Hungary’s leading aluminum die-casting foundries, undertook a comprehensive development project in collaboration with Csaba Tool Kft. and DROIDX Kft., located in Ajka. The project was realized with the support of the European Union during the programming period of 2014-2020 under the Economic Development and Innovation Operational Program.

Csaba Metál Zrt. made significant progress in the field of Industry 4.0 (the fourth industrial revolution) through the implementation of the project titled “Support for Micro, Small and Medium-sized Enterprises and Supplier Integrators” financed by the European Union. As a result of the development, the introduced InforCom enterprise resource planning system enables automatic data processing, providing real-time support for leaders in both operational and strategic decision-making.

The program allowed for more optimal utilization of production capacities, leading to improved productivity and efficiency. With the system, production planning and other processes can be designed faster and more accurately. As part of the investment, Csaba Metál Zrt. also assisted the professional development of the other two participating companies, Csaba Tool Kft. and DROIDX Kft., through consultancy as an integrator. This support included the development of engineering, human resources, quality management, trade, and lean management (which optimizes processes by reducing time spent on non-value-added tasks) and the provision of educational materials to facilitate the effective use of the enterprise resource planning system.

Additionally, for Csaba Tool Kft., the existing workshop building expanded by nearly 500 square meters, significantly increasing the available operational area. The workshop was equipped with a ten-ton capacity crane to simplify material handling tasks. Two machining centers, a modern software package supporting tool design, and a new workstation were acquired during the development. The machining center is a multifunctional machine tool that replaces the work of multiple individuals. With a tool changer capable of using a large number of tools, it flexibly performs various mechanical operations, such as milling, drilling, tapping, and drilling-tapping. Each processing step is programmable and can be automatically executed with the highest precision. The server and IT infrastructure were expanded, and an informative short film about the company was produced.

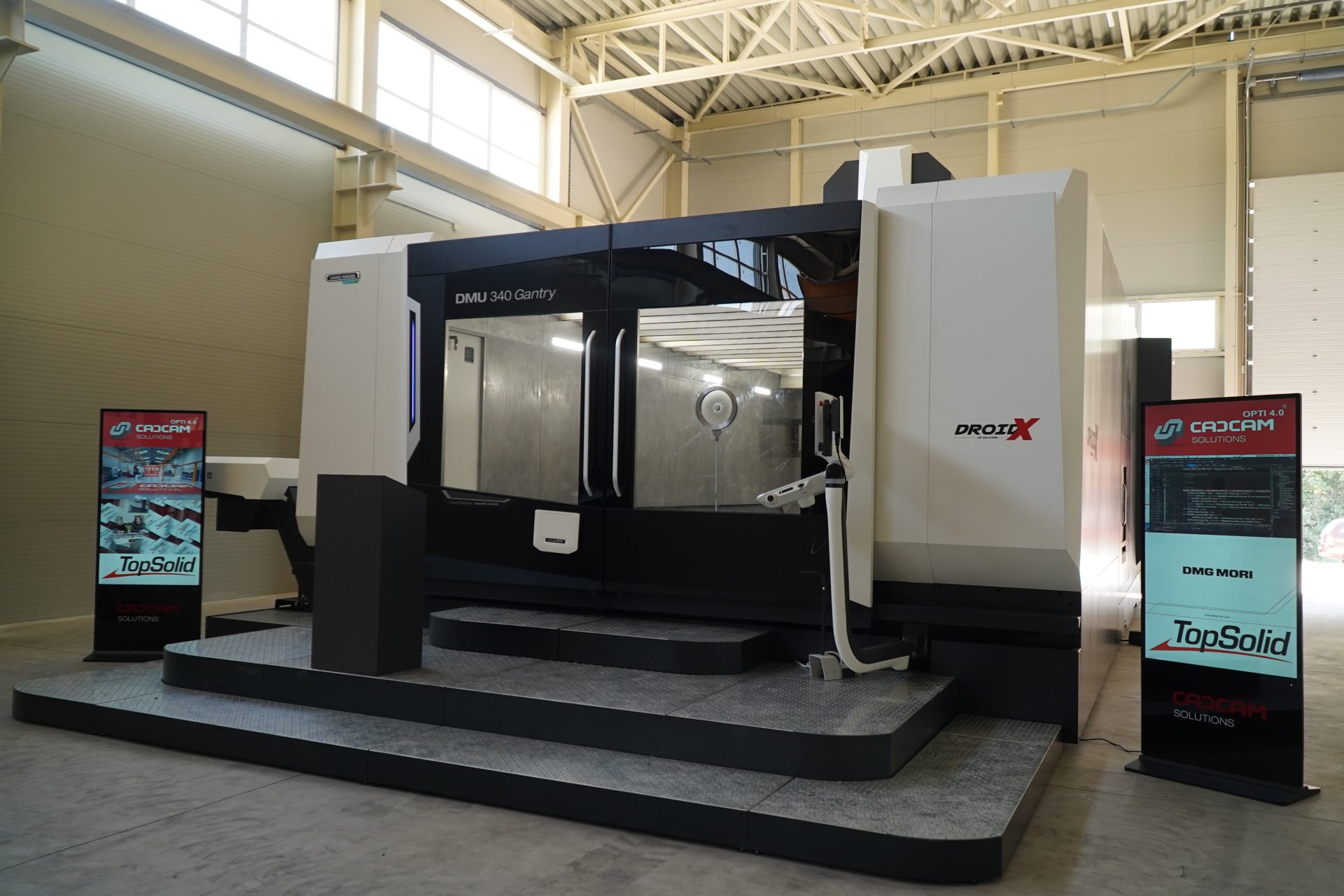

The equipment portfolio of DROIDX Kft., part of the consortium, was enriched with an important device due to continuous development: on July 22, 2022, they introduced a five-axis machining center in the expanded workshop area of 850 square meters within the project. This center specifically enabled the efficient production of large components. Through the grant, the company implemented a capacity-building and development project that enabled it to join the automotive supply chain, enhance collaboration with Csaba Metál Zrt., and explore valuable opportunities in foreign markets.

The program was implemented under the GINOP-1.3.3-16-2018-00069 project under the Economic Development and Innovation Operational Programme.

Find out more about the project in the Project Finder: Details