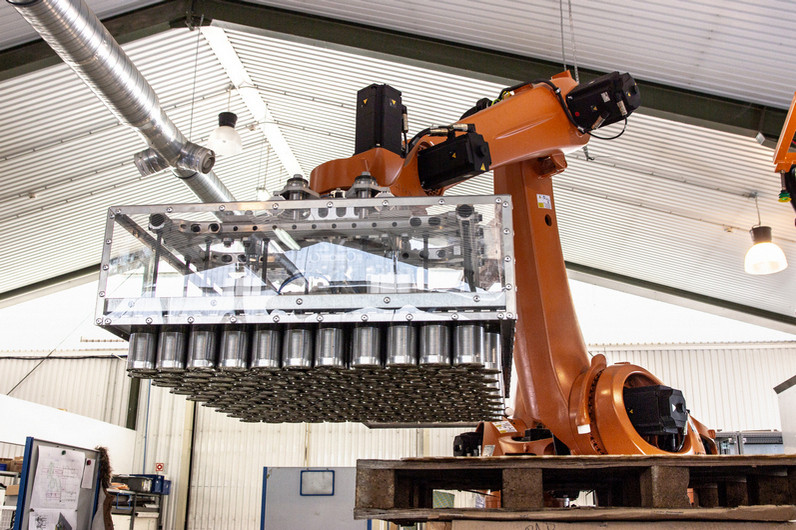

At Robot-X, work is in full swing! Thanks to European Union funding, their manufacturing capacity has skyrocketed, allowing them to fulfill orders faster and more efficiently.

Since its establishment, Robot-X has been specializing in industrial automation and robotics. As part of the project, two brand-new FANUC CNC machining centers and a Trens universal lathe have been added to the workshop. With these upgrades, the CNC department can now produce 4,000 parts per month, while the lathe section can manufacture 1,000 parts — essentially doubling production capacity, marking a significant step forward.

The company has also kept up with the latest in CAD and CAM software. Thanks to the newly acquired Esprit and Creo Light programs, programming is now faster, custom part design is far more efficient, and collaborative design work is now possible. Additionally, the team’s workflow is supported by six new PCs and a designer laptop.

Previously, painting and surface treatment had to be outsourced, which was not only time-consuming but also costly. However, the project enabled the company to establish a fully equipped painting facility at its Ózd plant. This includes a sandblasting booth, a powder coating chamber, a curing oven, and a conveyor system for moving workpieces. This setup allows for faster and more cost-effective production since every step — from design to painting — is now handled in-house. It also enables the company to deliver projects at an even higher standard of quality.

The development was implemented from EU funding in the project GINOP-1.2.1-14-2014-00207 under the Economic Development and Innovation Operational Programme Plus.

Find out more about the project in the Project Finder:Details